Cutting element for a bimetal saw chain

The lifetime of the cutting edge and therefore of saw chains until the next sharpening and inspection cycle can be significantly increased by using cutting elements in motorized chainsaws made of a laser-welded composite bimetal material. Hardness values of up to 750 HV and tensile strengths of up to 2,500 MPa can be achieved by using quenched and tempered high-speed steel. This makes it possible to use the saw for special purposes such as in emergencies by fire and rescue or for demolition work.

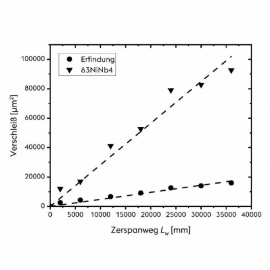

Comparative cutting tests with the laser-welded compound material – eight times the working life

Cutting tests were carried out on so-called lightweight woodchip boards, in order to assess the resistance to wear of the compound material in accordance with the invention. This type of board is made of long fibre, planed spruce or pine wood, in which case the fibres are bound together using cement. These types of cutting trials replicate practical cases extremely realistically, which is especially relevant with regard to abrasive impurities in wood which frequently occur, such as sand for example or typically through the earth or soil in the felling region.