Cutting element for a bimetal saw chain

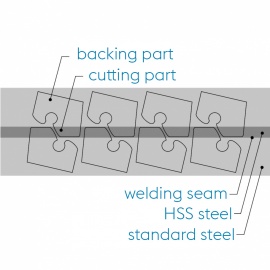

The lifetime of the cutting edge and therefore of saw chains until the next sharpening and inspection cycle can be significantly increased by using cutting elements in motorized chainsaws made of a laser-welded composite bimetal material. Hardness values of up to 750 HV and tensile strengths of up to 2,500 MPa can be achieved by using quenched and tempered high-speed steel. This makes it possible to use the saw for special purposes such as in emergencies by fire and rescue or for demolition work.

Producing stamped parts – High-quality preliminary material

The final product fulfils the highest demands with regards to precision, purity of material and weld-seam quality. Excellently processed bimetal strips result, as the starting material for chain links, which form the high end of chainsaws as regards cutting performance, braking safety and longevity.

Flawless weld-seams are the consequence of automated marking and removing any welding faults which may possibly occur. Excellent embossability on grounds of the low weld-seam hardness.

Efficient material utilisation

Chain links can be arranged in an alternating pattern in order to generate the highest possible material utilisation for the valuable bimetal strip. Waste is reduced in this way to significantly below 15%.

Flawless weld-seams are the consequence of automated marking and removing any welding faults which may possibly occur. Excellent embossability on grounds of the low weld-seam hardness.

Efficient material utilisation

Chain links can be arranged in an alternating pattern in order to generate the highest possible material utilisation for the valuable bimetal strip. Waste is reduced in this way to significantly below 15%.